Developing and providing environment-friendly products

Providing environment-friendly products (Reducing Scope 3 emissions)

Developing and providing cutting-edge decarbonization and low-carbon products

To contribute to the emergence of a decarbonized society, we are working to reduce our electricity costs (through reduced energy consumption) and are expanding our line of electric forklift products as replacements for our engine-powered forklifts. This effort is intended to popularize our clean and energy-efficient electric forklifts.

Sales of our new ALESIS electric forklift series, introduced in 2019, continue to grow outside Japan. In 2021, we began production of this model in China.

The series incorporates an environment-friendly Eco mode that contributes to extended operation. By enabling a reduction in power consumption, this innovation contributes to economical and eco-friendly operation.

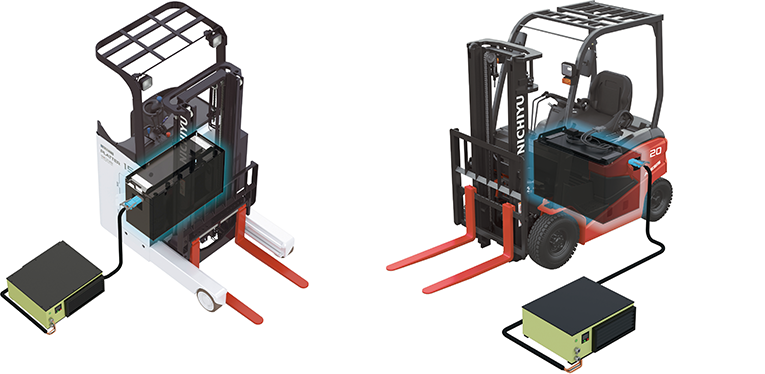

With growing customer demand for logistics equipment that supports CO2 emission reduction to achieve carbon neutrality, we have expanded our lineup of flagship products—the reach-type forklift PLATTER and the counterbalance forklift ALESIS—to include lithium-ion battery-powered models.

In 2021, we introduced the EDiA XL, a high-performance mid-sized electric forklift, in the European market, where such electric forklifts are becoming increasingly popular. This model boasts lowest-in-class electricity costs while delivering power and performance comparable to those of engine-powered forklifts. As a result, the EDiA XL can accommodate the work environment of a comparable engine-powered forklift truck. In 2022, we introduced this model onto the North American market.

In addition, this model won the Red Dot Design Award, a German international design award, under the Product Design category in July 2023. This unit earned high praise for its modern design and excellent performance thanks to its improved energy efficiency.

At the same time, in order to meet the needs of customers who use engine forklifts in a variety of environments, we continue to develop engine-powered forklifts that comply with emissions regulations even as they are becoming increasingly stringent every year across all our territories. Our new ERSIS engine-powered forklift, introduced in March 2022, can be equipped with a variety of engines manufactured by the Group. It exhibits excellent environmental performance that satisfies the latest emissions standards as well as outstanding economy thanks to its fuel efficiency.

Moreover, in an effort to work toward carbon neutrality, we collaborated with Nippon Kensetsu Kogyo Co., Ltd. in a joint demonstration test of a fuel-cell-powered forklift that burns no fuel and emits no CO2. It can be recharged with hydrogen in about three minutes, eliminating the need for the lengthy charging cycles typically required by electric forklifts.

Decarbonization of cargo-handling equipment in ports and coastal facilities

In order to help achieve the goal of carbon neutrality, we have launched an initiative with Mitsubishi Heavy Industries to reduce CO2 emissions at ports. We are thus contributing to the carbon neutrality of ports by developing new models of cargo handling equipment and converting existing equipment to hydrogen fuel cells with the goal of achieving zero carbon emissions in the future.

In September 2022, we delivered the first two units of our new Rubber-Tired Gantry Crane (RTG) to the Port of Kawasaki. Compared to conventional cranes, this innovative model features reduced greenhouse gas emissions and accommodates future conversion to hydrogen fuel cells. This model uses a smaller diesel generator to reduce the required engine displacement and output while also accommodating a storage battery with the same capacity as a conventional hybrid RTG. In addition, thanks to a new engine controller offering optimal and efficient combustion control, it satisfies the 2014 regulatory emissions standards of the Japanese Ministry of the Environment’s Specified Special Vehicle Exhaust Gas Control Act, reducing fuel consumption as well as emissions of CO2, NOx (nitrogen oxides), and PM (black smoke particulate matter). What’s more, its diesel generator can be replaced with a hydrogen fuel cell to respond to the near future in which an environment-friendly hydrogen supply infrastructure will be developed.