History

The History of Mitsubishi Logisnext Since 2017

| 2017.10.1 |

Mitsubishi Logisnext was born. |

|---|---|

| 2018.4.1 |

Mitsubishi Logisnext Europe B.V. and Mitsubish Logisnext Americas Inc. were established to act as regional headquarters companies in Europe and the Americas respectively. |

| 2018.11.13 |

Sales began for the laser guidance unmanned forklift “RACK FORK Auto .” |

| 2019.4.1 |

Thai group company Nichiyu Forklift (Thailand) Co., Ltd. changed its name to Logisnext Manufacturing (Thailand) Co., Ltd. |

| 2019.7.1 |

American group company Mitsubishi Logisnext Americas Inc. acquired all shares in Pon Material Handling, NA, Inc. (now Equipment Depot, Inc.) and made it a subsidiary. |

| 2019.11.1 |

The Logistics Test Center, a facility to trial equipment that uses cutting-edge and newly developed technologies, was established in the Mitsubishi Heavy Industries (MHI) Research & Innovation Center in Takasago. |

| 2019.11.1 |

The winder business was transferred to The Japan Steel Works, Ltd. |

| 2019.11.12 |

The ALESIS electric forklift was launched. |

| 2020.4.1 |

European group companies Rocla Oy, Unicarriers Europe A.B., and UniCarriers Manufacturing SPAIN S.A. changed their names to Mitsubishi Logisnext Europe Oy, Mitsubishi Logisnext Europe A.B., and Mitsubishi Logisnext Europe S.A. respectively. |

| 2020.4.1 |

The Technology Development Center was opened within Shiga Plant as a central base for technical development. |

| 2020.10.1 |

Direct sales companies were reorganized from eleven companies to nine. |

| 2020.10.1 |

Japanese group company UniCarrier Handling Systems Corporation changed its name to Logisnext Handling System Corporation. |

| 2020.10.6 |

The ALESIS electric forklift was presented with a 2020 Good Design Award. |

| 2021.4.1 |

The EDiA XL mid-sized counterbalanced electric forklift was launched for the European market. |

| 2021.4.1 |

US group companies Mitsubishi Caterpillar Forklift America Inc. and UniCarriers Americas Corporation changed their names to Mitsubishi Logisnext Americas (Houston) Inc. and Mitsubishi Logisnext Americas (Marengo) Inc. respectively. |

| 2021.6.1 |

A Japan-first laser-guided, unmanned forklift for refrigerated warehouses was jointly developed. |

| 2021.8.24 |

The PLATTER Auto H laser-guided automated forklift was launched. |

| 2022.3.17 |

An AGV demonstration center was opened in Finland at Mitsubishi Logisnext Europe Oy. |

| 2022.3.23 |

The ERSIS engine-powered forklift was launched. |

| 2022.6.1 |

US group company Equipment Depot, Inc. acquired all shares in the logistics equipment sales agents Norlift of Oregon, Inc. (now Equipment Depot Northwest, Inc.) and made it a subsidiary. |

| 2022.6.1 |

Trials of picking solutions for warehouse logistics that introduce automation and artificial intelligence using MHI Group’s ΣSynX system began. |

| 2022.6.6 |

A Japan-first laser-guided, unmanned forklift for −25°C freezer warehouses was launched. |

| 2023.1.1 |

An AGV demonstration center was opened in the US at Mitsubishi Logisnext Americas (Marengo) Inc. |

| 2023.4.1 |

There was a reorganization of the framework for the North American market. American regional headquarters company Mitsubishi Logisnext Americas Inc. changed its name to Mitsubishi Logisnext Americas Group Inc. Two companies under its umbrella were merged and established as the new Mitsubishi Logisnext Americas Inc. |

| 2023.4.6 |

Mitsubishi Logisnext started to work together with Rapyuta Robotics Co., Ltd. in the Japanese automated forklift business. |

| 2023.9.13 |

New, unmanned forklifts fitted with ΣSynX were launched at Logis-Tech Tokyo 2023 – The 3rd INNOVATION EXPO. |

| 2023.9.15 |

US group company Mitsubishi Logisnext Americas, Inc. and German company Jungheinrich AG established the joint venture Rocrich AGV Solutions, strengthening its AGV market in the North American market. |

Origins of Mitsubishi Logisnext

Mitsubishi Logisnext was launched as its own company in October 2017. The companies that combined to form it were four long-standing companies that had supported the logistics industry in Japan, and indeed the whole world, for many years as logistics equipment manufacturers. All four were pioneers that contributed diverse technologies and sales networks that they had independently developed and opened up as part of their respective histories.

One of our strengths at Mitsubishi Logisnext has been how we have flexibly taken on elements of these disparate approaches and maximized the advantages of this diversity.

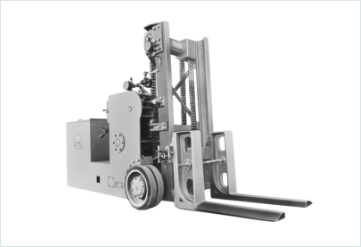

Nippon Yusoki (Nichiyu)

A solid footing in the Japanese market

Nippon Yusoki was the pioneering manufacturer of Japan’s first electric forklift, and developed its business mainly in Japan and elsewhere in Asia, particularly for mid-sized and small electric forklifts as well as logistics systems. It also led the industry in developing storage and transportation technologies, and worked to help improve the environment.

1939

- Japan’s first

Electric forklift developed.

1958

- Japan’s first

PLATTER stand-on electric reach forklift developed.

1971

- World’s first

Automated guided forklift developed and introduced.

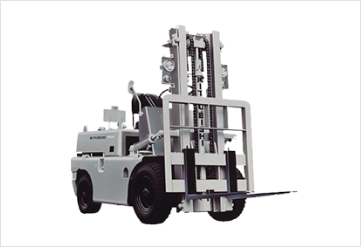

MHI’s Forklift Division

A focus on Europe and North America

MHI’s Forklift Division had its strengths in engine-powered forklifts, from the smallest models to the biggest, and production and sales progressed under both its Mitsubishi and Caterpillar brands, with its development focused on markets outside Japan, such as those in North America and Europe. With its advanced technological capabilities, which included independently developing major components such as diesel engines and gearboxes, it catered to a wide range of customer needs.

1970

Engine-powered forklifts started production.

2009

- World’s first

4- and 5-tonne hybrid forklifts introduced.

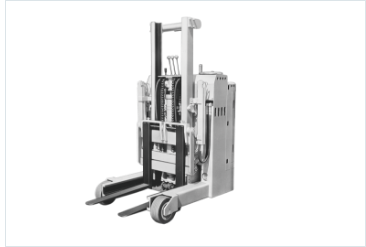

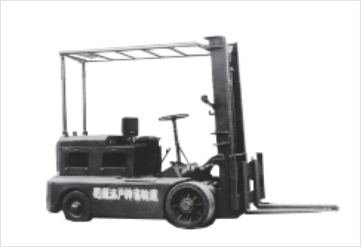

TCM

Advantages in large vehicles for handling specialized cargoes

TCM, which was the first company to produce engine-powered forklifts in Japan in 1949, was an industry pioneer. Many of its mechanical technologies from that time, such as basic mechanical structures and equipment, are widely used in forklifts even today. As well as engine-powered forklifts (especially large models with maximum loads of more than ten tonnes), TCM also had strengths in bucket-fitted vehicles (including shovel loaders and skid-steer loaders) and special transportation vehicles used in ports, steel mills, and shipyards.

1949

- Japan’s first

Toyo Carriers Manufacturing established. Engine-powered forklift (certified as an element of Japan’s Mechanical Engineering Heritage by the Japan Society of Mechanical Engineers) completed.

2008

Hybrid transfer crane presented with the second Japan Material Handling Grand Prize.

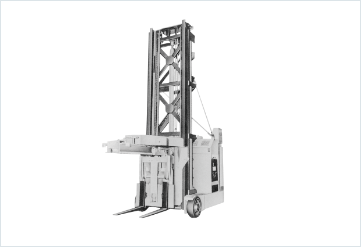

Nissan Forklift

Accumulated expertise in incorporating automotive technology and in-house engine innovations in product development

Nissan Motor Corporation’s Industrial Machinery Division , which had been set up in 1957, was spun off as Nissan Forklift in 2010. Its strengths lay in its technical development, which made use of its automotive technologies. As well as producing vehicles, it also sold engine units outside of the Nissan Group . Even after it became part of the UniCarrier Group, and now as part of Mitsubishi Logisnext, it is involved in manufacture and sales as the group company Global Component Technologies Corporation.

1975

Nissan Motor starts production at the Murayama Plant (following a transfer from the Nissan Shatai Kyoto Plant)

1986

- World’s first

Production and sales of H01 and H02 Series small engine vehicles with full floating cabs begin.

2003

Production and sales of the AGRES forklift, with compact, electronically controlled gasoline/LPG engines (developed jointly with MHI) begin.